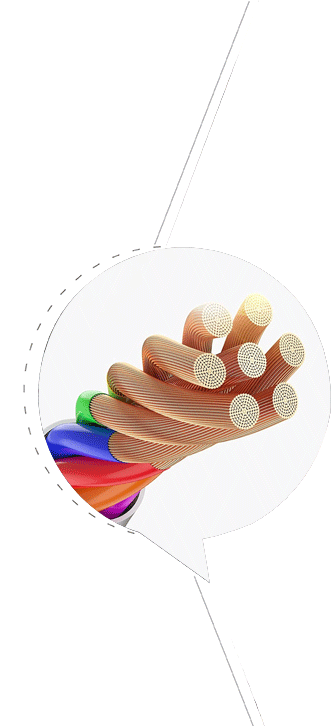

Shaft-mounted aluminium ffoyle est a traditional sheet-mounted aluminium ffoyle processionaliter in cylindrici, quod potest crescat totalis longitudinem unum fragmen aluminium ffoyle, cum 20000 metris in unum hastile. Hoc est fortior excussus et est magis arcte involutus filum in usu. Et hoc modo, quod non potest devita constant downtime pro filum mutationes, reducere numerum filum articulis et inferioribus deficiens rate.

+86-0519-86488610

Applicationem Scope:

Hoc est in altus-productivity data fune, ipsum tenuis funem, Minl cable, ut HDLM, USB, coaxial funem, etc.

Product parametri:

| Structura | Crassities | Proportionalis (G / M²) | Density (M² / kg) |

| Alu9 pet12 | 23MIC | 43 | 23 |

| Alu9 pet15 | 26Moed | 48 | 21 |

| Alu9 pet19 | 30MIC | 54 | 19 |

| Alu9 Pet23 | 34MIC | 60 | 17 |

| Alu12 pet12 | 26Moed | 52 | 19 |

| Alu12 pet15 | 29MIC | 56 | 18 |

| Alu12 pet19 | 33MIC | 62 | 16 |

| Alu12 Pet23 | 37MIC | 67 | 15 |

| Alu12 Pet36 | 50MMMIC | 87 | 12 |

| Alu15 pet19 | 36MMIC | 70 | 14 |

| Alu25 pet12 | 39MIC | 87 | 12 |

| Alu25 Pet23 | 50MMMIC | 102 | 10 |

| Alu40 pet12 | 54MIC | 127 | 8 |

| Alu40 pet15 | 57MIC | 131 | 8 |

| Alu40 Pet23 | 65MIC | 143 | 7 |

| Alu40 Pet36 | 78MIC | 161 | 6 |

| Alu50 pet12 | 64MIC | 154 | 6 |

| Alu50 pet15 | 67MIC | 158 | 6 |

| Alu50 pet23 | 75MIC | 170 | 6 |

| Antiphon interiorem diameter ID: 52mm, 76mm (charta pipe, ferrum pipe aut plastic pipe) | |||

| Minimum Width: 5mm maximam latitudinem: 1600mm Diam Diameter: 250mm ~ 650mm | |||

depictio producti:

Shaft-mounted aluminium ffoyle Est specialis aluminium ffoyle uber quod fundatur in altum qualitas aluminium ffoyle materia et vulnus aut fixum in hastile per praecisione processus.

Product Features

High æstus Resistentia: Aluminium Frigilum habet optimum summus temperatus resistentia et idoneam usum in extrema temperatus environments.

Optimum Tlubing: Non est optimum obice proprietatibus ad lucem, Gas et humorem, et apta variis applications quod requirit aut humorem, proofing.

Levisight et altum vires: Aluminium Ffil ipsum habet PERFUSORIUS characteristics, et simul, quod est fortis satis ad sustinere usum sub summus celeritas gyrationis vel gravibus onus conditionibus.

Fortis customizability: a varietate widths, crassitudines et shaft diametres potest provisum secundum mos necessitates ad aptet ad diversas apparatu et utitur.

Environmental Tutela: Potest esse recycled et reused, quod adjuvat ad redigendum resource vastum et occurrat in requisita sustineri progressionem.

Scope / Application missionibus

I. Packaging Industry

Food packaging, summus celeritas automatic packaging machinarum propter cibum, beverages, dairy products, etc, providebit airtightness et praesidium pro products.

Medical Packaging: Used enim humorem probationem, lux-probationem et signavit packaging medicamenta ad curare uber qualitas.

Cosmetics et cotidie eget packaging: late in signationem et packaging processus of products ut ad toothpaste et cutis crepito.

II. Industrial vestibulum

Cable et linea protegens, sicut materia in materia ad exteriores lavacrum funem vel lineas, amplio facultatem resistere electro intercessiones.

Thermal Nulla materiae: in aedificia et aer-condiciones apparatu ut pars calor praesidium vel velit layer.

III. Printing et psalmi agri

Label printing substrati: praebet lenis superficies et altum vires ad altus-finem pittacia ut patet printing effectus.

Excorative film et transferre amet: usus est durabile et pulchra materiae in scaenae ut billboards et domum appliance ornamentum.

IV. Mechanica apparatu et Automation Applications

Roll materiam pertractatio apparatu: propter automated productio processus apparatu ut coating, secans et rewinding.

Certamini instrumentis: propter signantes components in altus-praecisione apparatu in occursum requisita mechanica components pro materia stabilitatem.

V. AEROSPACE et Automotive Industry

Thermal Nulla et reflective materiae, in scelerisque tincidunt components of aircraft et automobiles ad redigendum calor damnum.

Lightweight components: usus est ad Lightweight materiae intra et extra vehiculo corpus ad amplio Fuel efficientiam.

Changzhou Yuzisenhan Electronic Co, Ltd.

Changzhou Yuzisenhan Electronic Co, Ltd. quote Shaft-mounted aluminium ffoyle. sumus Shaft-mounted aluminium ffoyle manufacturer et Shaft-mounted aluminium ffoyle elit. Societas nostra plures lineas productionis habet: unum potentissimum artifices in fabricatione domestica ferrei aeris vestiti, ferro infixo aereo vestito, aluminio aereo vestito.

Societas nostra aerea vestita est, aluminium cupreum vestitum, aeneum ferro infixa instrumenti technicae artis, necnon instrumentorum professionalium probatio Condidit plenam qualitatem certitudinis systematis ut in tuto collocetur producta societatis qualitatem strictam subeant a rudibus materiis ad productos perfectos. Societas nostra transiit 1S09000: 2000 qualitas administrationis systematis certificationis.

Liberum consilium cum peritis nostris.

Quaeso nobis rogationes tuas et suggestiones mitte. Respondebimus ad nuntium tuum prompte.

Popular products

nuntium

-

industria nuntium 2025-04-24

Aquarum induta Aluminium Wire (CCA Wire) Est facti vulgaris arbitrium pro antenna systems propter suam unique compositum de lu...

See More -

industria nuntium 2025-04-17

Copper vester ferro filum (ccs filum) est a versatile et sumptus-effective solutio ad grounding systems in electrica et telecommunic...

See More -

industria nuntium 2025-04-10

Aeris iactaret ferro filum (CCS filum) Est versatile et sumptus-effective materia usus est in telecommunications, electrica gr...

See More -

industria nuntium 2025-04-03

Cypripedium vestis ferro filum : A composita materia cum optimum perficientur Copper vester ferro filum est composi...

See More -

industria nuntium 2025-03-27

I. De partes CCS filum CCS filum est a key materia usus est in altilium nexu systems ad consequi electrica hospites...

See More -

industria nuntium 2025-03-20

Secundum ad latest Search results, in propria applications de CCA Wire (aeris FILIUS FILUM) In constructione industria sunt u...

See More

Shaft-mounted aluminium ffoyle Scientia Industriae

Key partes Shaft-mounted aluminium ffoyle In packaging Machinery et Electio Guide

I. Et core partes Shaft-mounted aluminium ffoyle In packaging machinery

Stabilitatem summus celeritate packaging

Et aluminium ffoyle necessitates ad aequaliter vulnere in sagittam core ad vitare quassans vel solveret per operationem (ut scelerisque packaging apparatus potest pervenire celeritate 500m / min).

Causa: et effectus ex eccentricitas de hastili-mounted aluminium ffoyle (≤0.1mm) in signing qualis est Points packaging machinis.

Clavem carrier de obice proprietatibus

Extend in PLUTEUM Vita cibum per oxygeni / aqua vapor obice Aluminium ffoyle (ut oxygeni permeability ≤0.1cm³ / M² · · 24h cum crassitudine est 12μm).

Compatibility cum machinatione

In interiore diametrum in sagittis core (communiter 76mm, 152mm) necessitatibus ad inserere solvit solvit in packaging machina ad vitare labore (quidam apparatu requirit aer expansion shaft fixation).

II. Key lectio parametri et technica Indicatores

| Parameter | Industria vexillum | Electio Guidance |

|---|---|---|

| Crassities | 6-30μm (9-12μm typical pro cibo packaging) | ≥30μm ad Emi protegit; ut tenues quod 6μm pro Candy involuti. |

| Tensile viribus | ≥0mpa (longitudinalis) | ≥100mpa requiritur ad summus celeritas packaging ne breakage. |

| Superficiem curatio | Single / Geminus, postesque Glossa, coatings | Matte anti-baculum coating pro scelerisque; ROSIO-repugnans coating pro pharmaceutical ffoyle. |

| Core materiales | Plastic (Abs), ferro, charta tubo | Immaculatam ferro cores enim umidus ambitus; Plastic corores ad Lightweight necessitates. |

| Width tolerantia | ± 0.5mm (Latin) | ± 0.2mm requiritur ad summus celeritas slitting machinis. |

| Calor sigillum perficientur | ≥8n / 15mm Sigillum fortitudinem | ≥15n / 15mm ad RECORD Pouch applications. |

III. Commune problems et solutions

Problema: Renous in ore Aluminium Foil Roll

Ratio: Slitting Slitting Tensio aut deformatio in Shaft Core

Countermeasures: Usus laser slitting technology et reprehendo rotunditatem Core (tolerantia ± 0.05mm).

Problema: electrostatic adsorption de pulveris in rudibus

Causa: summus celeritas friction generat stabilis electricity (magis obvious cum humiditas est

IV. Industry application casibus

PHARMACEUTICICAL Packaging: 7μm Shaft-mounted Aluminium Ffil (obsequium cum USP classis vi signa) est composita cum PVC pro tabula papulas.

Dairy Product Sigillum: quod Securus-Lacrimam consilio Aluminium Ffil (calor Inconveniendi fortitudinem 10-15n / 15mm) amplio user usus est yogurt calicem.

V. Future Trends

Intelligentes Coil Management: Track Aluminium Coil Batches et Refid Tags ad consequi automatic volumine mutatio.

Sustainable materiae: environmentally amica solutions ad recyclable cores (ut favum chartam tubulis) et aluminium ffoyle (8μm pro 12μm) .

EN

EN